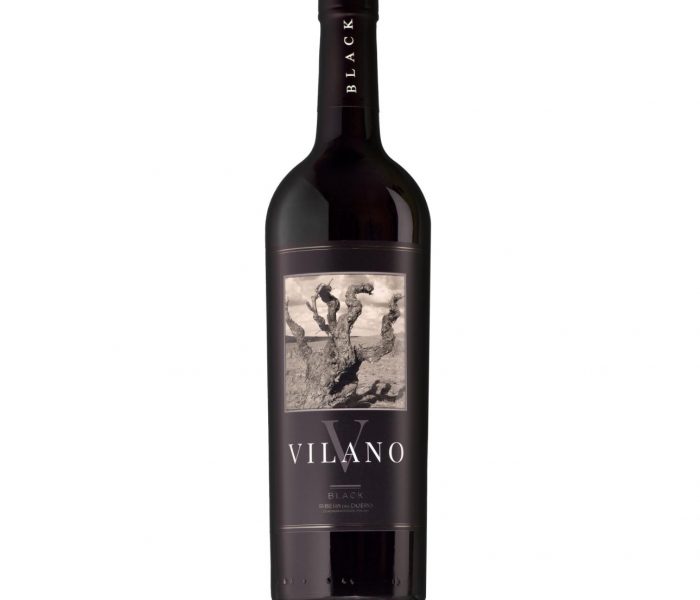

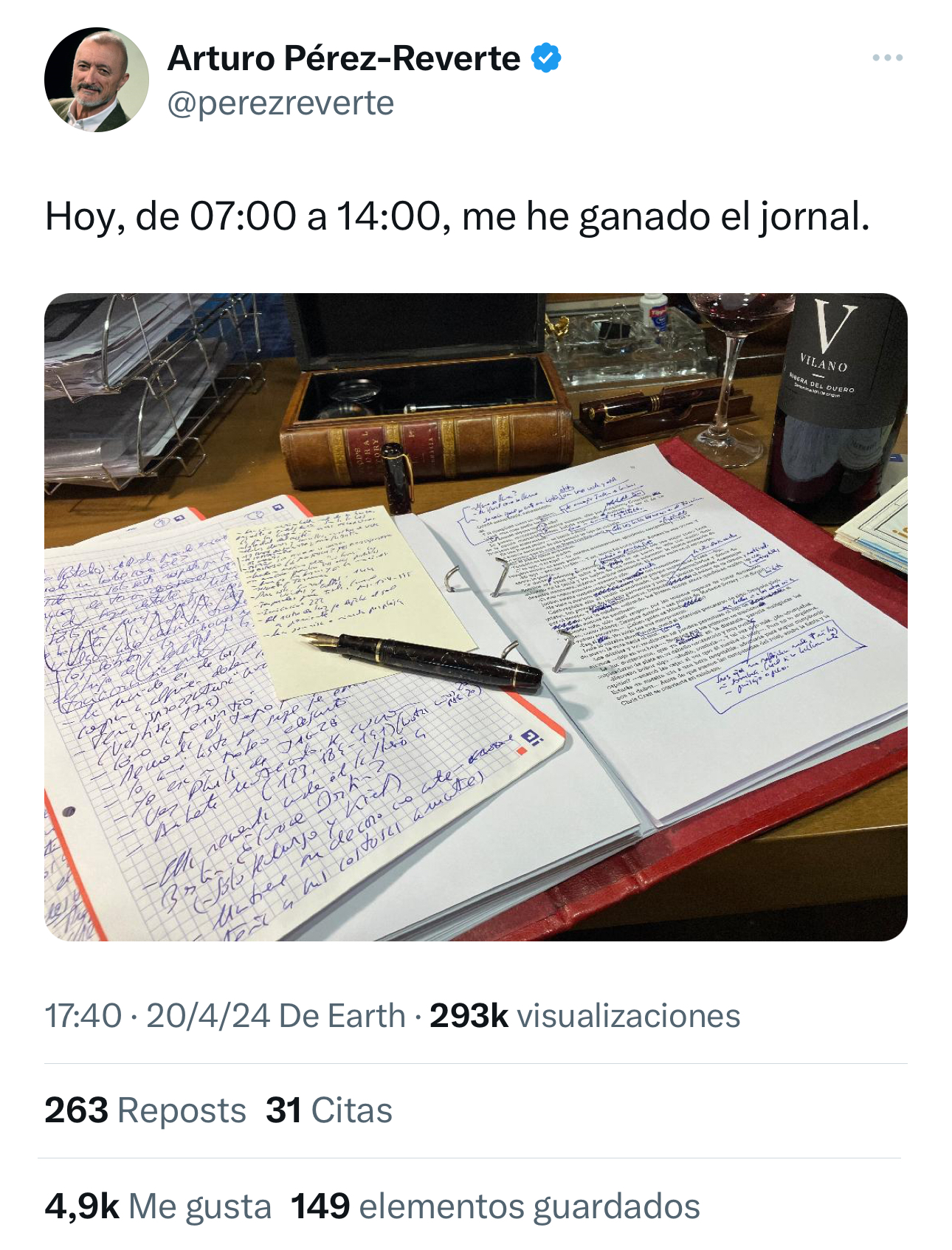

RIBERA DEL DUERO EN ESTADO PURO

RECONOCIDOS COMO UNOS DE LOS MEJORES VINOS DEL MUNDO

Vilano es el sabor de la tierra, de las uvas más selectas; el fruto de la búsqueda incesante de la excelencia. Tras ella, un equipo humano trabaja día a día para mantener viva su tradición con esfuerzo, conocimiento y pasión.

La bodega mezcla las últimas técnicas de tecnología e ideas transformadoras con tradición para crear vinos únicos que están sorprendiendo a nivel internacional.

NUESTROS VINOS

Ubicada en Pedrosa de Duero, (Burgos), una de las zonas privilegiadas donde tradicionalmente se ha dedicado al viñedo de alta calidad. Bodegas Viña Vilano S. Coop. cuenta con más de 250 hectáreas de viñedo de la variedad “Tinta Fina” o “Tinta del País”, (Tempranillo) y una producción potencial anual de 2 millones de kilos de uva de alta calidad.

ÚLTIMAS NOTICIAS

CONTACTA CON NOSOTROS

Vinos con Espíritu

Bodegas VILANO está ubicada en la localidad de Pedrosa de Duero, provincia de Burgos, considerada internacionalmente como la zona más privilegiada de la D.O. Ribera del Duero, con viñedo antiguo que data ya de su fundación en 1957.

Avenida Tinta del País, nº 2

09314 Pedrosa De Duero · Burgos · España

+34 947 530 029